-

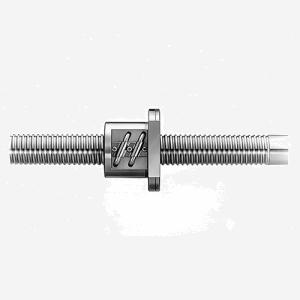

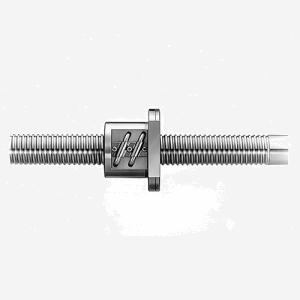

道岔摩擦连接器和滚珠丝杠都是机械连接件,用于连接和固定不同部件。但它们的结构和原理有所不同。 道岔摩擦连接器是一种利用摩擦力将两个部件连接在一起的连接器。它由两个零件组成,其中一个零件有凸起的齿轮,另一个零件有一个凹槽,齿轮可以在凹槽中旋转。当两个零件组合在一起时,摩擦力将它们连接在一起,形成稳定的连接。 滚珠丝杠是一种利用滚珠在螺旋线上滚动,转换旋转运动为直线运动的机械传动件。它由螺纹杆、螺纹套和滚珠组成。当螺纹杆旋转时,滚珠在螺旋线上滚动,并带动螺纹套移动,从而实现旋转运动转换为直线运动。 因此,道岔摩擦连接器和滚珠丝杠在结构和原理上有所不同,应用场景也不同。道岔摩擦连接器主要用于连接轻载荷和低速运动的部件,例如电子设备、玩具等,而滚珠丝杠则主要用于工业机械、自动化设备、机床等需要高精度和高负载的场合。

道岔摩擦连接器和滚珠丝杠都是机械连接件,用于连接和固定不同部件。但它们的结构和原理有所不同。 道岔摩擦连接器是一种利用摩擦力将两个部件连接在一起的连接器。它由两个零件组成,其中一个零件有凸起的齿轮,另一个零件有一个凹槽,齿轮可以在凹槽中旋转。当两个零件组合在一起时,摩擦力将它们连接在一起,形成稳定的连接。 滚珠丝杠是一种利用滚珠在螺旋线上滚动,转换旋转运动为直线运动的机械传动件。它由螺纹杆、螺纹套和滚珠组成。当螺纹杆旋转时,滚珠在螺旋线上滚动,并带动螺纹套移动,从而实现旋转运动转换为直线运动。 因此,道岔摩擦连接器和滚珠丝杠在结构和原理上有所不同,应用场景也不同。道岔摩擦连接器主要用于连接轻载荷和低速运动的部件,例如电子设备、玩具等,而滚珠丝杠则主要用于工业机械、自动化设备、机床等需要高精度和高负载的场合。 -

道岔摩擦连接器和滚珠丝杠是两种不同的机械连接件。 道岔摩擦连接器是用于连接铁路道岔的机械连接件,它通过摩擦力来保持道岔的位置和稳定性。道岔摩擦连接器通常由两个半圆形的部件组成,它们可以通过螺栓或钩子连接在一起,使道岔保持正确的位置和角度。 滚珠丝杠是一种用于传递旋转运动和线性运动的机械连接件,它由滚珠和螺纹杠组成,通过滚珠在螺纹杠上的滚动运动来实现线性运动。滚珠丝杠通常用于机械设备中需要进行精准的线性运动的地方,例如机床、自动化生产线等。 虽然道岔摩擦连接器和滚珠丝杠都是机械连接件,但它们的使用场景和原理都有很大的差异。

道岔摩擦连接器和滚珠丝杠是两种不同的机械连接件。 道岔摩擦连接器是用于连接铁路道岔的机械连接件,它通过摩擦力来保持道岔的位置和稳定性。道岔摩擦连接器通常由两个半圆形的部件组成,它们可以通过螺栓或钩子连接在一起,使道岔保持正确的位置和角度。 滚珠丝杠是一种用于传递旋转运动和线性运动的机械连接件,它由滚珠和螺纹杠组成,通过滚珠在螺纹杠上的滚动运动来实现线性运动。滚珠丝杠通常用于机械设备中需要进行精准的线性运动的地方,例如机床、自动化生产线等。 虽然道岔摩擦连接器和滚珠丝杠都是机械连接件,但它们的使用场景和原理都有很大的差异。 -

步进电机的滚珠丝杠速度取决于许多因素,如步进电机的型号、驱动器的性能、电源电压和电流、负载的惯性和摩擦力等。一般来说,步进电机的滚珠丝杠速度可以通过调整电源电压和电流来控制,但是过高的速度可能会导致步进电机失步或损坏,因此需要根据具体情况进行调整。另外,选择合适的驱动器和控制器也可以提高步进电机的滚珠丝杠速度和精度。

步进电机的滚珠丝杠速度取决于许多因素,如步进电机的型号、驱动器的性能、电源电压和电流、负载的惯性和摩擦力等。一般来说,步进电机的滚珠丝杠速度可以通过调整电源电压和电流来控制,但是过高的速度可能会导致步进电机失步或损坏,因此需要根据具体情况进行调整。另外,选择合适的驱动器和控制器也可以提高步进电机的滚珠丝杠速度和精度。 -

Grinding of ball screws is a common practice in the manufacturing industry, particularly in the production of precision machinery and equipment. Ball screws are widely used in applications that require accurate linear motion, such as CNC machines, robotics, and aerospace systems. The grinding process is used to produce high-precision, high-quality ball screws that meet the exacting requirements of these applications. There are several steps involved in the grinding of ball screws. The first step is to inspect the screw to ensure that it is straight and free from defects. The screw is then placed in a grinding machine, where it is ground to the desired size and shape. The grinding process involves removing material from the screw using abrasive wheels or belts. The screw is then polished to improve its finish and reduce friction. The grinding of ball screws is typically performed by specialized companies with the expertise and equipment to produce high-quality screws. These companies use advanced CNC grinding machines and techniques to ensure that the screws are ground to the exact specifications required by their customers. The finished screws are then inspected to ensure that they meet the highest standards of quality and performance. Overall, the grinding of ball screws is an essential process in the production of precision machinery and equipment. By producing high-quality, accurate ball screws, manufacturers can ensure that their products perform reliably and meet the needs of their customers.

Grinding of ball screws is a common practice in the manufacturing industry, particularly in the production of precision machinery and equipment. Ball screws are widely used in applications that require accurate linear motion, such as CNC machines, robotics, and aerospace systems. The grinding process is used to produce high-precision, high-quality ball screws that meet the exacting requirements of these applications. There are several steps involved in the grinding of ball screws. The first step is to inspect the screw to ensure that it is straight and free from defects. The screw is then placed in a grinding machine, where it is ground to the desired size and shape. The grinding process involves removing material from the screw using abrasive wheels or belts. The screw is then polished to improve its finish and reduce friction. The grinding of ball screws is typically performed by specialized companies with the expertise and equipment to produce high-quality screws. These companies use advanced CNC grinding machines and techniques to ensure that the screws are ground to the exact specifications required by their customers. The finished screws are then inspected to ensure that they meet the highest standards of quality and performance. Overall, the grinding of ball screws is an essential process in the production of precision machinery and equipment. By producing high-quality, accurate ball screws, manufacturers can ensure that their products perform reliably and meet the needs of their customers.

相关问题

相关产品

扫码添加企业微信

声明

网站免责声明

访问者在接受本网站服务之前,请务必仔细阅读本条款并同意本声明。访问者以任何方式登陆本网站以及通过任何方式直接、间接使用本网站,都将被视作是对本声明全部内容的无异议认可;如有异议,请立即跟本网站协商,并取得本网站的书面同意意见。

1 、访问者在从事与本网站相关的所有行为(包括但不限于访问浏览、利用、转载、宣传介绍)时,必须以善意且谨慎的态度行事;访问者不得故意或者过失损害或者弱化本网站的各类合法权利与利益,不得利用本网站以任何方式直接或者间接从事违反法律、行政法规和违背社会公德的行为,且访问者应当恪守下述承诺:

(1) 传输和利用信息符合国家及地方政府关于互联网网络信息安全的法规、条例、管理办法及其它相关法律法规的规定;符合公序良俗;

(2) 不将本网站以及与之相关的网络服务用作非法用途以及非正当用途;

(3)不干扰和扰乱本网站以及与之相关的网络服务;

(4)遵守与本网站以及与之相关的网络服务的协议、规定、程序和惯例等。

2 、任何单位及个人不得利用本网站来获取商业秘密,窥探个人隐私,侵犯他人知识产权,制造、传播和散布污蔑、诽谤、恐吓他人的言论和消息。一经发现,本网站将立即无限期终止对该用户的任何服务,并报告国家有关公安、行政、司法机关,追究其相关法律责任。

3 、对于因他人的违法或违约行为造成其它招聘单位或个人损害的,由侵权人直接承担法律责任,本网站对此不负任何责任;对招聘单位与求职者之间的一切人事纠纷,由当事双方自行协商解决,与本网站无关。

4 、当本网站以链接形式推荐其他网站内容时,本网站并不对这些网站或资源的可用性负责,且不保证从这些网站获取的任何内容、产品、服务或其他材料的真实性、合法性,对于任何因使用或信赖从此类网站或资源上获取的内容、产品、服务或其他材料而造成(或声称造成)的任何直接或间接损失,本网站均不承担任何责任。

5 、访问者在本网站注册提供的一切用户资料,除政府部门、司法机关等依照法定程序要求本网站披露用户相关资料的或征得用户书面同意外,不会将用户的任何资料以任何方式泄露给任何一方。本网站根据执法单位之要求或为公共安全之目的提供用户资料的,在此情况下之任何披露,本网站均得免责。

6 、任何由于黑客攻击、计算机病毒侵入或发作、因政府管制而造成的暂时性关闭等影响网络正常经营及其他之不可抗力原因而造成的用户资料泄露、丢失、被盗用或被篡改等,本网站均得免责。

7 、 由于用户将用户密码告知他人或与他人共享注册账户,由此导致的任何用户资料泄露、信誉损失等不利影响,本网站不负任何责任。

8 、本声明未涉及的问题参见国家有关法律法规,当本声明与国家法律法规冲突时,以国家法律法规为准。