-

滚珠丝杠反向器是一种用于改变转向方向的装置,通常应用于滚珠丝杠传动系统中。它可以将旋转方向由正向改为反向,以实现机械设备的双向运动。该装置由两个主要组件组成:输入轴和输出轴,它们通过一个滚珠丝杠传动连接。 滚珠丝杠反向器的工作原理是利用滚珠丝杠传动的特性,通过改变传动方向来实现反向转动。当输入轴转动时,滚珠丝杠传动将其转换为沿着滚珠丝杠的线性运动,然后再将其传递到输出轴上。当反向器开启时,输出轴会沿着与输入轴相反的方向转动。 滚珠丝杠反向器通常由一个离合器控制,可以手动或自动地切换正向和反向转动。在一些应用中,反向器还会配备限位开关和传感器,以便监测输出轴的位置和速度。

滚珠丝杠反向器是一种用于改变转向方向的装置,通常应用于滚珠丝杠传动系统中。它可以将旋转方向由正向改为反向,以实现机械设备的双向运动。该装置由两个主要组件组成:输入轴和输出轴,它们通过一个滚珠丝杠传动连接。 滚珠丝杠反向器的工作原理是利用滚珠丝杠传动的特性,通过改变传动方向来实现反向转动。当输入轴转动时,滚珠丝杠传动将其转换为沿着滚珠丝杠的线性运动,然后再将其传递到输出轴上。当反向器开启时,输出轴会沿着与输入轴相反的方向转动。 滚珠丝杠反向器通常由一个离合器控制,可以手动或自动地切换正向和反向转动。在一些应用中,反向器还会配备限位开关和传感器,以便监测输出轴的位置和速度。 -

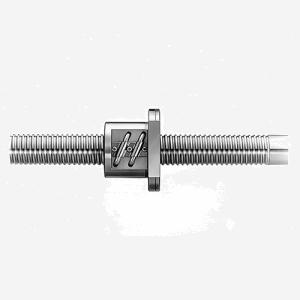

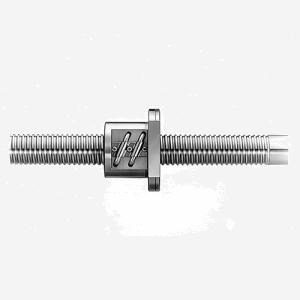

题目:滚珠丝杠及其应用研究 摘要:滚珠丝杠是一种常用的传动元件,在机械制造中有着广泛的应用。本文主要研究了滚珠丝杠的基本原理、结构形式、选型方法以及在机械制造中的应用。通过对滚珠丝杠的分析,发现其具有传动效率高、精度高、运行平稳等优点,因此在机床、自动化设备、航空航天等领域得到了广泛应用。本文还重点研究了滚珠丝杠的设计及制造,以及其在机床加工中的应用。通过实验验证,证明了滚珠丝杠在机床加工中的应用效果良好,具有较高的加工精度和稳定性,能够满足机床加工的要求。 关键词:滚珠丝杠;机床加工;传动效率;精度;稳定性 Abstract: Ball screw is a commonly used transmission element, which has a wide range of applications in mechanical manufacturing. This paper mainly studies the basic principle, structural form, selection method and application of ball screw in mechanical manufacturing. Through the analysis of ball screw, it is found that it has the advantages of high transmission efficiency, high precision and smooth operation, so it has been widely used in machine tools, automation equipment, aerospace and other fields. This paper also focuses on the design and manufacture of ball screw, and its application in machine tool processing. Through experimental verification, it is proved that ball screw has good application effect in machine tool processing, with high processing accuracy and stability, which can meet the requirements of machine tool processing. Keywords: ball screw; machine tool processing; transmission efficiency; accuracy; stability

题目:滚珠丝杠及其应用研究 摘要:滚珠丝杠是一种常用的传动元件,在机械制造中有着广泛的应用。本文主要研究了滚珠丝杠的基本原理、结构形式、选型方法以及在机械制造中的应用。通过对滚珠丝杠的分析,发现其具有传动效率高、精度高、运行平稳等优点,因此在机床、自动化设备、航空航天等领域得到了广泛应用。本文还重点研究了滚珠丝杠的设计及制造,以及其在机床加工中的应用。通过实验验证,证明了滚珠丝杠在机床加工中的应用效果良好,具有较高的加工精度和稳定性,能够满足机床加工的要求。 关键词:滚珠丝杠;机床加工;传动效率;精度;稳定性 Abstract: Ball screw is a commonly used transmission element, which has a wide range of applications in mechanical manufacturing. This paper mainly studies the basic principle, structural form, selection method and application of ball screw in mechanical manufacturing. Through the analysis of ball screw, it is found that it has the advantages of high transmission efficiency, high precision and smooth operation, so it has been widely used in machine tools, automation equipment, aerospace and other fields. This paper also focuses on the design and manufacture of ball screw, and its application in machine tool processing. Through experimental verification, it is proved that ball screw has good application effect in machine tool processing, with high processing accuracy and stability, which can meet the requirements of machine tool processing. Keywords: ball screw; machine tool processing; transmission efficiency; accuracy; stability -

4006滚珠丝杠使用的钢珠直径一般为4mm。

4006滚珠丝杠使用的钢珠直径一般为4mm。 -

题目:滚珠丝杠在机械制造中的应用及优化设计 摘要:滚珠丝杠作为一种常见的传动元件,在机械制造中具有广泛的应用。本文以滚珠丝杠的原理和结构为基础,重点分析了其在机床等设备中的应用。通过对滚珠丝杠的性能参数进行分析,提出了优化设计方案,包括材料、制造工艺、润滑方式等方面。最后,通过实验验证,证明了优化设计方案的有效性。 关键词:滚珠丝杠;机械制造;应用;优化设计;实验验证 Abstract: As a common transmission element, ball screw has a wide range of applications in mechanical manufacturing. Based on the principle and structure of ball screw, this paper focuses on the application of ball screw in machine tools and other equipment. Through the analysis of the performance parameters of ball screw, optimization design schemes are proposed, including materials, manufacturing processes, lubrication methods, and so on. Finally, through experimental verification, the effectiveness of the optimization design scheme is proved. Keywords: ball screw; mechanical manufacturing; application; optimization design; experimental verification

题目:滚珠丝杠在机械制造中的应用及优化设计 摘要:滚珠丝杠作为一种常见的传动元件,在机械制造中具有广泛的应用。本文以滚珠丝杠的原理和结构为基础,重点分析了其在机床等设备中的应用。通过对滚珠丝杠的性能参数进行分析,提出了优化设计方案,包括材料、制造工艺、润滑方式等方面。最后,通过实验验证,证明了优化设计方案的有效性。 关键词:滚珠丝杠;机械制造;应用;优化设计;实验验证 Abstract: As a common transmission element, ball screw has a wide range of applications in mechanical manufacturing. Based on the principle and structure of ball screw, this paper focuses on the application of ball screw in machine tools and other equipment. Through the analysis of the performance parameters of ball screw, optimization design schemes are proposed, including materials, manufacturing processes, lubrication methods, and so on. Finally, through experimental verification, the effectiveness of the optimization design scheme is proved. Keywords: ball screw; mechanical manufacturing; application; optimization design; experimental verification

相关产品

扫码添加企业微信

声明

网站免责声明

访问者在接受本网站服务之前,请务必仔细阅读本条款并同意本声明。访问者以任何方式登陆本网站以及通过任何方式直接、间接使用本网站,都将被视作是对本声明全部内容的无异议认可;如有异议,请立即跟本网站协商,并取得本网站的书面同意意见。

1 、访问者在从事与本网站相关的所有行为(包括但不限于访问浏览、利用、转载、宣传介绍)时,必须以善意且谨慎的态度行事;访问者不得故意或者过失损害或者弱化本网站的各类合法权利与利益,不得利用本网站以任何方式直接或者间接从事违反法律、行政法规和违背社会公德的行为,且访问者应当恪守下述承诺:

(1) 传输和利用信息符合国家及地方政府关于互联网网络信息安全的法规、条例、管理办法及其它相关法律法规的规定;符合公序良俗;

(2) 不将本网站以及与之相关的网络服务用作非法用途以及非正当用途;

(3)不干扰和扰乱本网站以及与之相关的网络服务;

(4)遵守与本网站以及与之相关的网络服务的协议、规定、程序和惯例等。

2 、任何单位及个人不得利用本网站来获取商业秘密,窥探个人隐私,侵犯他人知识产权,制造、传播和散布污蔑、诽谤、恐吓他人的言论和消息。一经发现,本网站将立即无限期终止对该用户的任何服务,并报告国家有关公安、行政、司法机关,追究其相关法律责任。

3 、对于因他人的违法或违约行为造成其它招聘单位或个人损害的,由侵权人直接承担法律责任,本网站对此不负任何责任;对招聘单位与求职者之间的一切人事纠纷,由当事双方自行协商解决,与本网站无关。

4 、当本网站以链接形式推荐其他网站内容时,本网站并不对这些网站或资源的可用性负责,且不保证从这些网站获取的任何内容、产品、服务或其他材料的真实性、合法性,对于任何因使用或信赖从此类网站或资源上获取的内容、产品、服务或其他材料而造成(或声称造成)的任何直接或间接损失,本网站均不承担任何责任。

5 、访问者在本网站注册提供的一切用户资料,除政府部门、司法机关等依照法定程序要求本网站披露用户相关资料的或征得用户书面同意外,不会将用户的任何资料以任何方式泄露给任何一方。本网站根据执法单位之要求或为公共安全之目的提供用户资料的,在此情况下之任何披露,本网站均得免责。

6 、任何由于黑客攻击、计算机病毒侵入或发作、因政府管制而造成的暂时性关闭等影响网络正常经营及其他之不可抗力原因而造成的用户资料泄露、丢失、被盗用或被篡改等,本网站均得免责。

7 、 由于用户将用户密码告知他人或与他人共享注册账户,由此导致的任何用户资料泄露、信誉损失等不利影响,本网站不负任何责任。

8 、本声明未涉及的问题参见国家有关法律法规,当本声明与国家法律法规冲突时,以国家法律法规为准。